Hyundai Unleashes Atlas Robots in Georgia Plant: A $21B Bet on the Future of Humanoid Automation in the U.S.

In April 2025, Hyundai Motor Group made headlines by deploying Boston Dynamics’ Atlas robots at its new electric vehicle (EV) “Metaplant” in Georgia, USA. The announcement, part of Hyundai’s broader $21 billion investment in its U.S. operations through 2030, marks a potentially transformative moment in global manufacturing — not just because of the amount spent, but because of the type of robots involved.

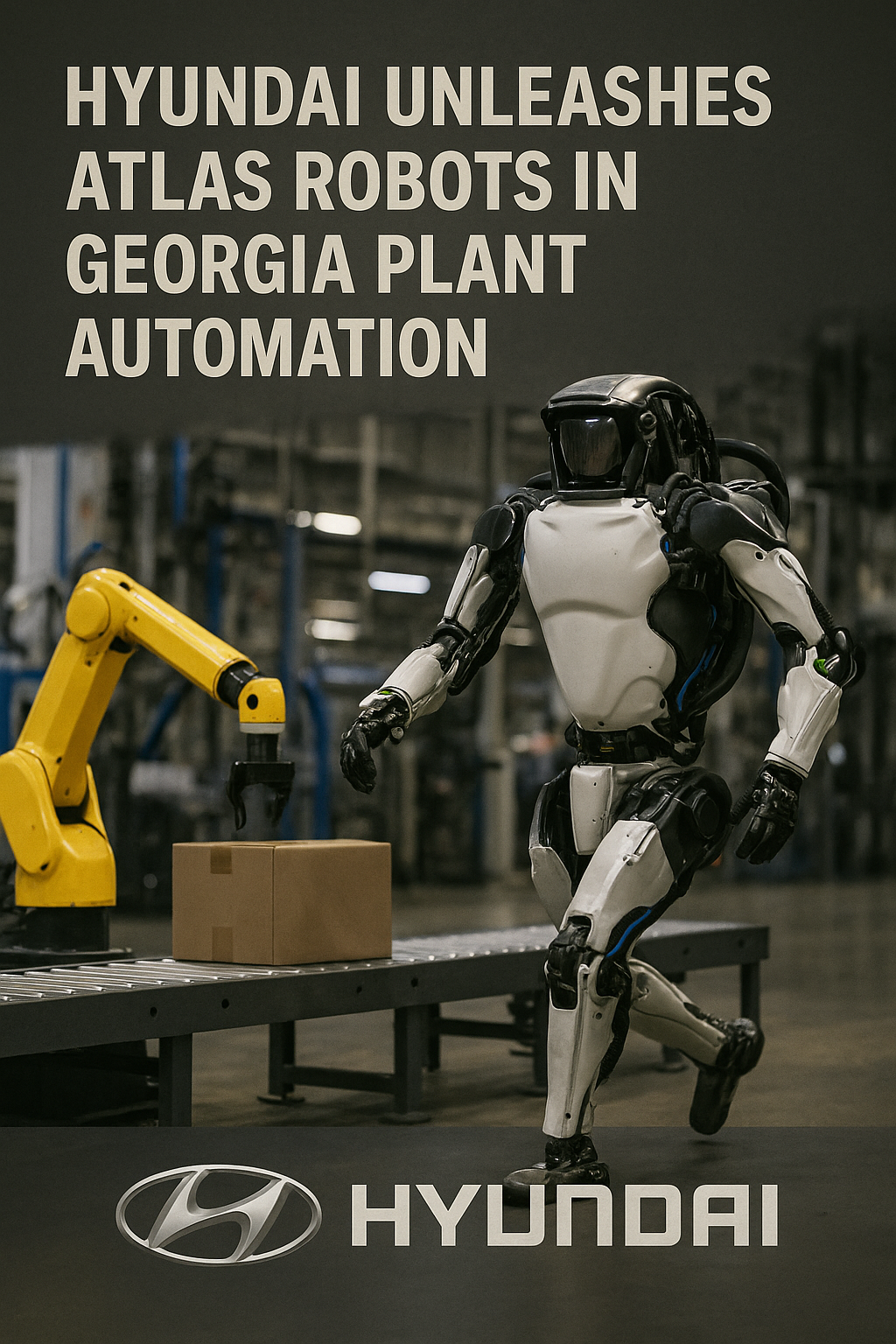

Unlike the thousands of robotic arms already ubiquitous in car factories around the world, Hyundai is introducing humanoid robots — the bipedal Atlas models — into production settings. While Atlas has long dazzled internet audiences with parkour and backflips, the current generation is being refitted for real-world utility in industrial environments.

What makes this bold move notable isn’t just its ambition — it’s the fact that very few companies in the world are attempting to operationalize humanoid robots at scale. Hyundai’s Georgia plant is now ground zero for what could be the next industrial revolution. But how does this compare to what other global manufacturing and logistics giants are doing in automation?

Let’s dive into the current landscape of robotic automation and see how Hyundai’s strategy stacks up.

Part 1: The Atlas Revolution – From Viral Robot to Factory Worker

Boston Dynamics, now a subsidiary of Hyundai, recently retired its original hydraulically powered Atlas robot in favor of a new generation of electric-powered Atlas units, optimized for industrial tasks rather than acrobatics.

These next-gen Atlas robots are being deployed in Hyundai’s Georgia Metaplant to perform tasks such as:

- Moving parts and materials around the plant floor

- Assisting with tasks in areas where humans face ergonomic strain

- Performing repetitive or dangerous work with high precision

- Supporting a modular, flexible production line that can adapt to different EV models

What sets Atlas apart?

- Mobility: Unlike traditional robotic arms or even wheeled mobile robots, Atlas can move in human-designed environments without needing major structural changes to the factory. It can walk, bend, and maneuver in tight spaces.

- Dexterity: With advanced manipulators and computer vision, it can pick up and manipulate a wide range of objects — even ones it hasn’t seen before.

- Adaptability: Atlas uses reinforcement learning and large-scale simulation training to handle dynamic environments and unexpected challenges.

By integrating Atlas into the EV assembly process, Hyundai is betting big on a vision of flexible, intelligent, humanoid automation that could, if successful, revolutionize how cars (and other products) are built.

But is Hyundai the only one thinking this big?

Part 2: Tesla – The Cautionary Tale of Over-Automation

Tesla has long positioned itself as the vanguard of smart manufacturing, with Elon Musk famously declaring years ago that “the factory is the product.” However, Tesla’s early experiment with extreme automation in the production of the Model 3 is now widely viewed as a lesson in the risks of going too far, too fast.

What happened at Tesla?

- In its Fremont, California factory, Tesla built one of the most highly automated lines in the world.

- Robotic systems were meant to handle everything — including final vehicle assembly.

- The result? Bottlenecks, breakdowns, and missed production targets.

Elon Musk later acknowledged:

“Humans are underrated. Excessive automation at Tesla was a mistake.”

Today, Tesla has found a more balanced approach:

- Robots dominate battery production, welding, and painting — areas where automation is mature.

- Humans remain critical in final assembly and quality control, where judgment, touch, and adaptability matter most.

Tesla also continues to explore advanced automation, including Dojo, its custom AI training supercomputer, and even Tesla Bot (Optimus), a humanoid robot still in early development — though not yet in production use.

Part 3: Toyota – A Philosophy of Human-Robot Balance

Toyota is often cited as the gold standard of manufacturing efficiency, thanks to its famous Toyota Production System (TPS). While the company has been using automation for decades, its approach is deeply rooted in a human-first philosophy.

Toyota’s guiding principles:

- Robots assist, not replace, skilled workers.

- Processes are not automated until they are fully understood by humans.

- Craftsmanship (“monozukuri”) is seen as irreplaceable in certain domains.

For instance:

- Robots handle welding, painting, and some assembly tasks.

- However, semi-automated cells allow skilled workers to oversee and adapt processes dynamically.

- Final assembly often includes human-led inspections and adjustments.

In contrast to Hyundai’s leap into humanoid robotics, Toyota has chosen a path of incremental, conservative automation, focused on sustainability, reliability, and continuous improvement.

Part 4: Amazon – Logistics Automation at a Scale Never Seen Before

While Hyundai is aiming to transform manufacturing, Amazon has already transformed logistics using robots at an enormous scale.

After acquiring Kiva Systems in 2012, Amazon now operates with more than 750,000 robots across its global fulfillment network. These include:

- Autonomous mobile robots (AMRs) that transport shelves of goods to human pickers.

- Proteus, Amazon’s first fully autonomous robot that can move freely around humans.

- AI-driven optimization systems for sorting, routing, and packing.

Key difference:

- Amazon doesn’t use humanoid robots.

- It focuses on task-specific automation and modular robotic units, prioritizing speed and volume over physical generalization.

Still, Amazon is a leading indicator of what wide-scale labor automation can look like — particularly in e-commerce and distribution.

Part 5: BMW, Mercedes-Benz, and the European Smart Factory

German automakers have pioneered a highly digitalized, interconnected approach to automation through the Industry 4.0 framework.

BMW’s “iFACTORY” Concept:

- Modular production that adapts quickly to new vehicle models.

- AI-powered quality inspection and predictive maintenance.

- Use of collaborative robots (cobots) that work side-by-side with human workers.

Mercedes-Benz’s “MO360” Digital Ecosystem:

- Digital twins of entire production lines.

- Real-time data integration across plants worldwide.

- Customization of vehicles down to the individual component level.

Unlike Hyundai’s humanoid robotics initiative, these companies are investing in system-level automation — emphasizing software, data, and optimization over mechanical revolution.

Part 6: Why Hyundai’s Move is So Bold — and So Risky

Let’s be clear: no one has successfully deployed humanoid robots at scale in a high-volume industrial setting. Hyundai is attempting something that is, as of now, largely theoretical.

Potential Benefits:

- Greater flexibility across shifting production needs.

- Safer, more ergonomic working environments.

- Labor cost reduction over time, especially in tight job markets.

Challenges:

- Durability: Can Atlas handle months or years of daily industrial use?

- Safety: How will human workers and humanoid robots safely coexist?

- Economics: Will the cost of development, integration, and maintenance justify the performance?

- Acceptance: Will workers, unions, and regulators embrace this change?

By placing Atlas into a real production environment, Hyundai is effectively beta-testing the future of work.

Final Thoughts: Is This the Future of Manufacturing?

Hyundai’s $21 billion U.S. automation push is more than a financial statement — it’s a philosophical one. At a time when the manufacturing industry is under immense pressure from labor shortages, supply chain disruptions, and global competition, the company is choosing to lead with vision rather than caution.

Humanoid robots may still be a long way from replacing humans in most industries. But they don’t have to replace anyone to be useful. If Hyundai’s experiment works — even partially — it could change how factories are built, how jobs are designed, and how humans and machines collaborate.

One thing is clear: the line between science fiction and production reality just got a little blurrier.

What’s your take?

Do you think humanoid robots like Atlas will become a norm in the factory of the future, or is Hyundai jumping the gun on technology that isn’t ready?